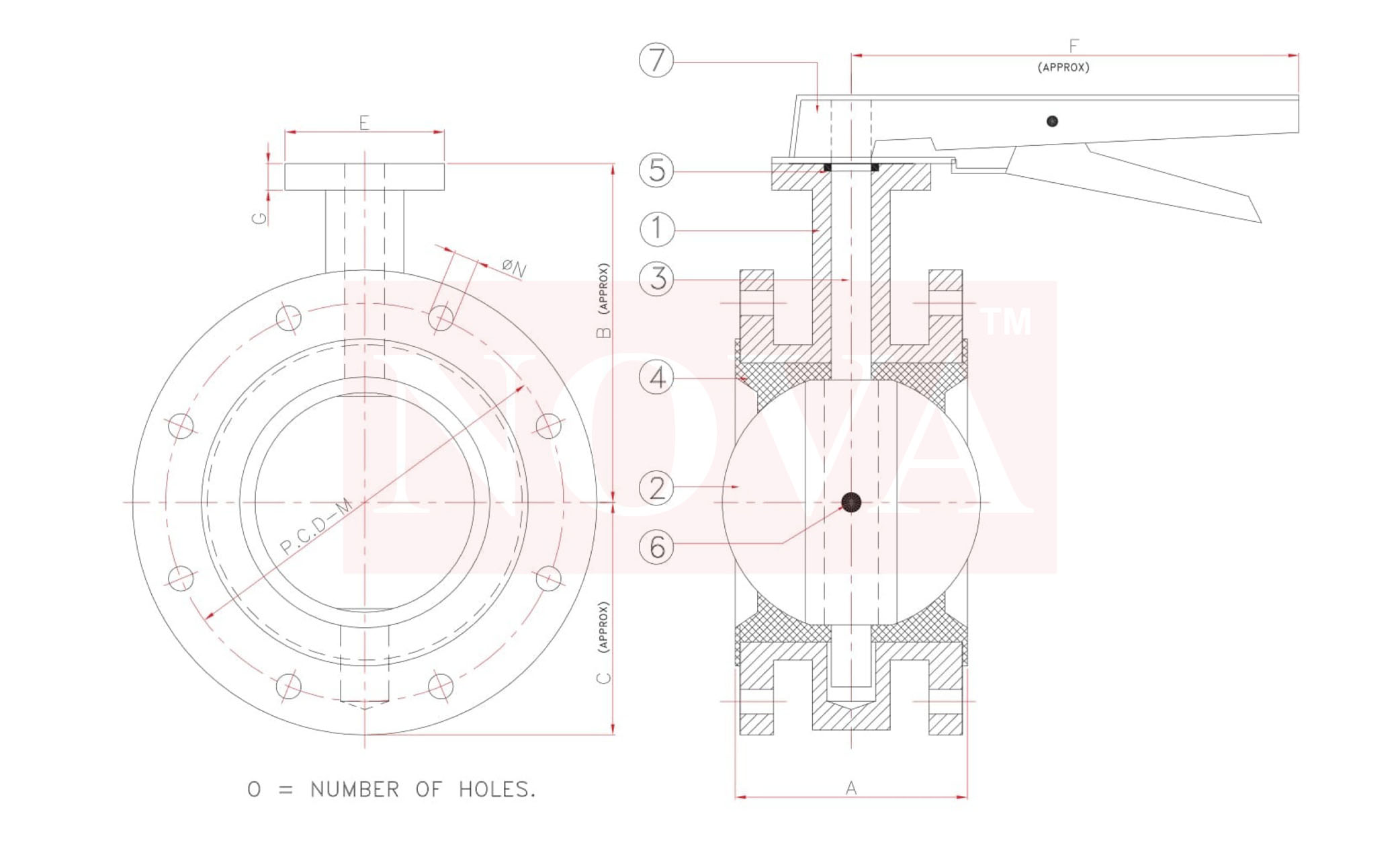

Double Flange Butterfly Valves - Central Disc

We are, Nova Valves, is one of the leading and trusted manufacturer of high quality Double Flange Central Disc Butterfly Valves. Our Double Flange Butterfly Central Disc Valves are highly recommended in Industrial Use and, Commercial Use.

Size Table - SE/DF-BFV/50-200

| SIZE | A | B | C | E | F | G | FLANGE MOUNTING (I.S.O 5211) | |

|---|---|---|---|---|---|---|---|---|

| MM | INCH | |||||||

| 50 | 2" | 108 | 125 | 85 | 65 | 180 | 15 | F05 |

| 65 | 2 1/2" | 112 | 135 | 95 | 65 | 180 | 15 | F05 |

| 80 | 3" | 114 | 155 | 102 | 65 | 215 | 15 | F05 |

| 100 | 4" | 127 | 160 | 112 | 65 | 215 | 15 | F05 |

| 125 | 5" | 140 | 180 | 134 | 65 | 265 | 15 | F05 |

| 150 | 6" | 140 | 210 | 147 | 65 | 265 | 15 | F05 |

| 200 | 8" | 152 | 250 | 175 | 75 | 325 | 15 | F07 |

NOTE :- M,N,O AS PER REQUIREMENT

TESTING

| PRESSURE RATING | HYDROSTATIC SHELL TEST | HYDROSTATIC SEAT TEST | ||

|---|---|---|---|---|

| Kg/CM2 | PSI | Kg/CM2 | PSI | |

| PN16 | 22 | 310 | 16 | 225 |

| PN10 | 15 | 210 | 10 | 140 |

Material Description

| NO | PARTS NAME | MATERIALS |

|---|---|---|

| 1 | BODY | CAST IRON/CAST STEEL/S.S.304-316 |

| 2 | DISC | CAST IRON/CAST STEEL/S.S.304-316 |

| 3 | SPINDLE | SS 410/304/316 |

| 4 | BODY LINING | NITRILE/E.P.D.M./SILICON/VITON/HYPALON |

| 5 | 'O' RING | NITRILE/E.P.D.M. |

| 6 | PIN | S.S.304/316 |

| 7 | LEVER | M.S. FABRICATED |

SEAT TEMPERATURE RANGE

| SEAT TYPE | TEMPERATURE RANGE | |

|---|---|---|

| Min. | Max. | |

| NITRILE | -13°F(-25°C) | 212°F(100°C) |

| EPDM | -13°F(-25°C) | 250°F(120°C) |

| SILICON | -58°F(-50°C) | 356°F(180°C) |

| VITON | -23°F(-5°C) | 392°F(200°C) |

| HYPALON | -4°F(-20°C) | 250°F(120°C) |

CONFORMITY TO CODES & STANDARDS

| NO | PARTS NAME |

|---|---|

| 1 | GENERAL DESIGN & MANUFACTURE :- BS 5155 / API 609 / EN 593 / IS 13095 |

| 2 | VALVE FACE TO FACE DIMENSION :- BS 5155 / ISO 5752 / API 609 |

| 3 | TOP FLANGE DRILLING :- ISO 5211 |

| 4 | VALVE INSPECTION & TESTING :- BS 6755 PART - I / API 598 / EN 12266-1 |

| 5 | FLANGE STANDARD CONFORMITY :- ANSI 150 / ANSI 125 / BS 10 TAB D & E |

| IS 6392 NP 0.6 / 1.0 / 1.6 |

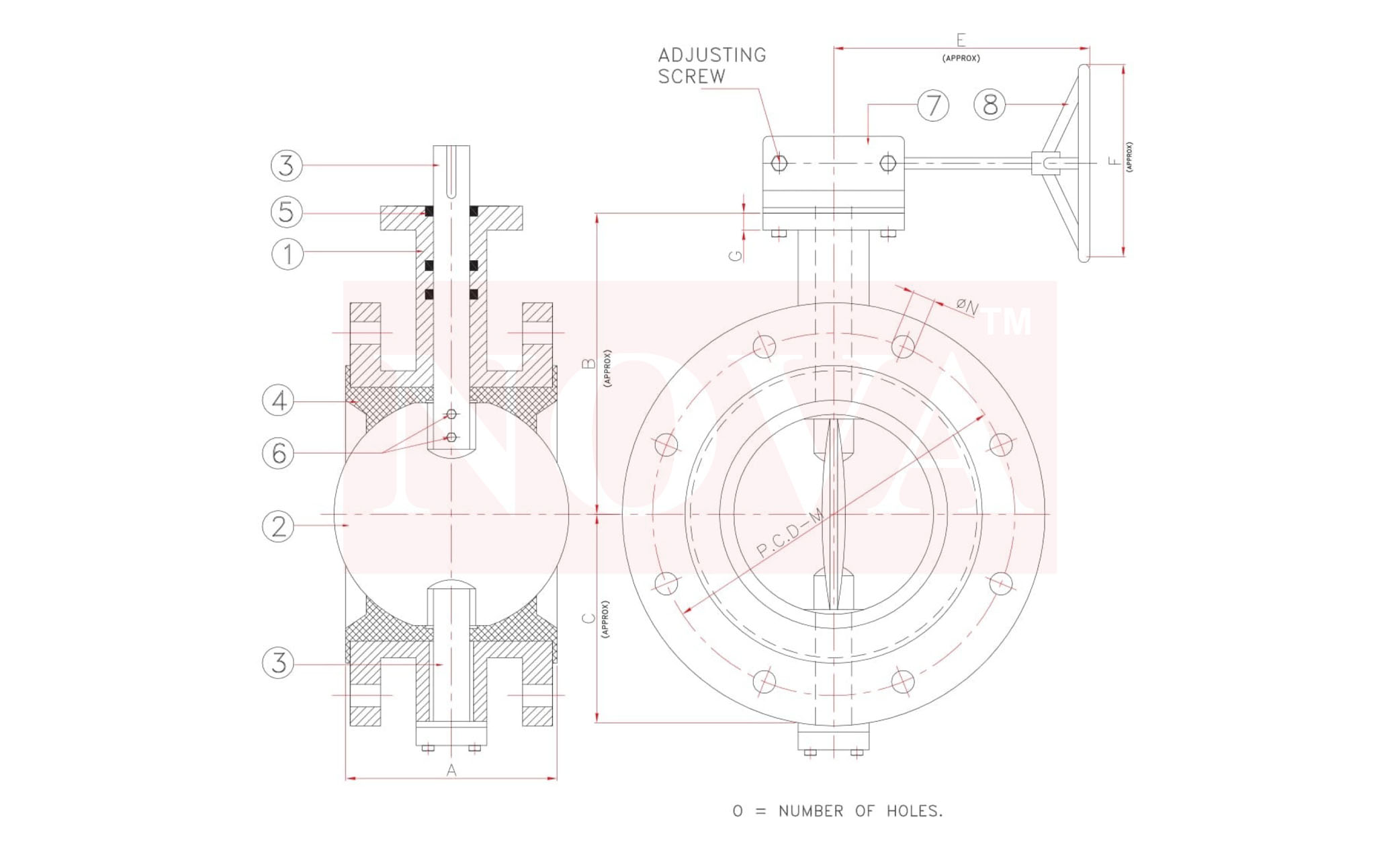

Material Description

| NO | PARTS NAME | MATERIALS |

|---|---|---|

| 1 | BODY | CAST IRON/CAST STEEL/S.S.304-316 |

| 2 | DISC | CAST IRON/CAST STEEL/S.S.304-316 |

| 3 | SPINDLE | SS 410/304/316 |

| 4 | BODY LINING | NITRILE/E.P.D.M./SILICON/VITON/HYPALON |

| 5 | 'O' RING | NITRILE/E.P.D.M. |

| 6 | HEX BOLT | S.S.304/316 |

| 7 | GEAR BOX | CAST IRON |

| 8 | HAND WHEEL | M. S. FABRICATED |

Size Table

| SIZE | A | B | C | E | F | G | FLANGE MOUNTING (I.S.O 5211) | |

|---|---|---|---|---|---|---|---|---|

| MM | INCH | |||||||

| 200 | 8" | 152 | 250 | 175 | 285 | 300 | 15 | F10 |

| 250 | 10" | 165 | 285 | 208 | 285 | 350 | 18 | F10 |

| 300 | 12" | 178 | 310 | 227 | 285 | 350 | 18 | F10 |

| 350 | 14" | 190 | 340 | 275 | 300 | 350 | 22 | F12 |

| 400 | 16" | 216 | 376 | 308 | 305 | 500 | 22 | F14 |

| 450 | 18" | 222 | 390 | 373 | 305 | 500 | 24 | F14 |

| 500 | 20" | 229 | 425 | 408 | 370 | 500 | 26 | F16 |

| 600 | 24" | 267 | 500 | 464 | 350 | 600 | 26 | F16 |

NOTE :- M,N,O AS PER REQUIREMENT

TESTING

| PRESSURE RATING | HYDROSTATIC SHELL TEST | HYDROSTATIC SEAT TEST | ||

|---|---|---|---|---|

| Kg/CM2 | PSI | Kg/CM2 | PSI | |

| PN16 | 22 | 310 | 16 | 225 |

| PN10 | 15 | 210 | 10 | 140 |

| PN6 | 9 | 126 | 6 | 84 |

SEAT TEMPERATURE RANGE

| SEAT TYPE | TEMPERATURE RANGE | |

|---|---|---|

| Min. | Max. | |

| NITRILE | -13°F(-25°C) | 212°F(100°C) |

| EPDM | -13°F(-25°C) | 250°F(120°C) |

| SILICON | -58°F(-50°C) | 356°F(180°C) |

| VITON | -23°F(-5°C) | 392°F(200°C) |

| HYPALON | -4°F(-20°C) | 250°F(120°C) |

SEAT TEMPERATURE RANGE

| NO | PARTS NAME |

|---|---|

| 1 | GENERAL DESIGN & MANUFACTURE :- BS 5155 / API 609 / EN 593 / IS 13095 |

| 2 | VALVE FACE TO FACE DIMENSION :- BS 5155 / ISO 5752 / API 609 |

| 3 | TOP FLANGE DRILLING :- ISO 5211 |

| 4 | VALVE INSPECTION & TESTING :- BS 6755 PART - I / API 598 / EN 12266-1 |

| 5 | FLANGE STANDARD CONFORMITY :- ANSI 150 / ANSI 125 / BS 10 TAB D & E |

| S 6392 NP 0.6 / 1.0 / 1.6 |